Is your engine making a ticking noise? Don't ignore it! Find out the possible causes and learn how to fix engine ticking noise with this helpful guide.

Possible Causes of Engine Ticking Noise

If you're experiencing a ticking noise in your engine, it's important to identify the source of the noise and address it promptly. The ticking noise could indicate an underlying issue that requires attention. Here are a few possible causes of engine ticking noise:

1. Lifter Noise

Ticking sounds often stem from the valvetrain, particularly the lifters. The lifters maintain proper contact between the camshaft and the valves. If the lifters become worn or dirty, they may not function correctly, resulting in a ticking noise.Lifter noise, often referred to as "valve lifter tick" or "valve train noise," is a common issue in internal combustion engines. It is a distinct tapping or ticking sound that can be heard coming from the engine compartment. Lifter noise is particularly noticeable when the engine is idling or running at low speeds. The noise can be quite annoying, but it may also indicate an underlying problem that needs attention.

Potential Causes of Lifter Noise

The lifter is a small hydraulic component that sits between the camshaft and the pushrod or rocker arm. Its purpose is to maintain proper valve clearance and ensure smooth operation of the valvetrain. When the lifter becomes worn or fails to maintain proper oil pressure, it can produce the characteristic ticking noise. There are several potential causes of lifter noise, including:

1.1. Low Engine Oil Level. Insufficient oil can lead to inadequate lubrication of the lifters and other engine components, resulting in increased noise.

1.2. Dirty or Contaminated Oil. Dirty or old engine oil can prevent proper lifter operation, causing noise.

1.3. Lifter Wear. Over time, lifters can wear due to constant friction, leading to increased clearances and noise.

1.4. Clogged Oil Passages. If oil passages become clogged with debris or sludge, it can impede the flow of oil to the lifters, affecting their performance.

1.5. Air in the Lifter. Sometimes, air can become trapped in the lifter, causing noise and reduced lifter function.

1.6. Lifter Collapse or Failure. In severe cases, a lifter may collapse or fail, leading to more significant engine issues and potential damage.

To address lifter noise

a. Check Engine Oil Level. Ensure that your engine has enough oil and that it is within the recommended range on the dipstick.

b. Change the Oil and Filter. If the engine oil is dirty or old, change it along with the oil filter. Use the oil type and viscosity recommended in your vehicle's owner's manual.

c. Use Additives. There are oil additives designed to clean and improve the performance of lifters. You can try using a reputable lifter treatment additive to see if it reduces the noise.

d. Avoid High RPMs. While dealing with lifter noise, avoid high engine speeds or aggressive driving. Gentle driving can help reduce stress on the lifters.

e. Professional Inspection. If the noise persists or if you suspect a serious issue, have a qualified mechanic inspect your engine. They can diagnose the specific cause of the lifter noise and recommend appropriate repairs.

Remember, lifter noise should not be ignored, as it can lead to more severe engine problems if left unaddressed. Timely maintenance and addressing any issues promptly can help keep your engine running smoothly and quietly.

2. Low Engine Oil

Insufficient oil or low oil pressure can lead to ticking noises in the engine. When the oil level is low, the moving parts of the engine may not receive proper lubrication, causing increased friction and ticking sounds.Engine Oil Circulation

To address Low Engine Oil

If you are experiencing a low engine oil situation in your vehicle, it's important to take immediate action to prevent potential damage to your engine. Here's what you should do:

2.1. Check the Oil Level. Park your vehicle on a level surface, turn off the engine, and wait a few minutes for the oil to settle in the oil pan. Locate the engine oil dipstick (usually with a yellow or orange handle) under the hood. Pull it out, wipe it clean with a cloth, reinsert it, and then pull it out again. Check the oil level; it should be between the "Min" and "Max" marks on the dipstick.

2.2. Add Oil if Necessary. If the oil level is below the "Min" mark or significantly low, you need to add more oil. To do this, find the oil filler cap on top of the engine (often labeled "Oil" or "Engine Oil") and remove it. Use a funnel to add the appropriate type and grade of motor oil recommended for your vehicle, as stated in the owner's manual. Avoid overfilling, as this can cause other issues.

2.3. Inspect for Leaks. If you frequently notice low engine oil levels, there may be an oil leak in the engine system. Look under the car for any signs of oil puddles or drips. If you find a leak or suspect one, it's essential to have it inspected and repaired by a qualified mechanic.

2.4. Monitor Oil Levels Regularly. After adding oil or resolving any leaks, keep a close eye on your oil levels. Regularly checking your oil level is crucial for maintaining your engine's health and catching any potential issues early.

2.5. Oil Change Schedule. Make sure you adhere to the recommended oil change schedule for your vehicle, as mentioned in the owner's manual. Regular oil changes are essential for keeping your engine lubricated and clean.

2.6. Address Warning Lights. If your car has an oil pressure warning light on the dashboard, pay attention to it. If it illuminates while driving, pull over safely, turn off the engine, and check the oil level immediately. Continuing to drive with low oil pressure can cause severe engine damage.

If you are unsure of how to check or add engine oil, or if you suspect a significant oil leak or engine issue, it's best to have your vehicle inspected by a professional mechanic to avoid any potential complications and ensure the problem is properly addressed.

3. Exhaust Manifold Leak

A leak in the exhaust manifold can result in a ticking or clicking noise. The exhaust gases escaping from the leak can create a distinct sound that is often more noticeable when the engine is cold.An exhaust manifold leak can indeed cause a ticking noise in your vehicle. The exhaust manifold is a crucial component that collects the exhaust gases from the engine cylinders and directs them into the exhaust system. It is usually made of cast iron or stainless steel and is bolted directly to the engine's cylinder head.

Exhaust Manifold

Exhaust Manifold Leak Leading Issues

When there is a leak in the exhaust manifold, it allows exhaust gases to escape before they reach the exhaust system. This can lead to several issues, including the following:

3.1. Ticking Noise. The most common and noticeable symptom of an exhaust manifold leak is a ticking or tapping noise coming from the engine compartment. This noise is typically more pronounced during acceleration or under load.

3.2. Engine Performance Issues. An exhaust manifold leak can cause a disruption in the proper backpressure in the exhaust system, leading to reduced engine performance, power, and fuel efficiency.

3.3. Burning Smell. If the exhaust gases are leaking near other engine components or onto the engine itself, you may notice a burning smell coming from under the hood.

3.4. Check Engine Light (CEL). In some cases, an exhaust manifold leak can trigger the Check Engine Light on your dashboard. The onboard diagnostic system may detect a problem with the air-fuel mixture or emissions due to the leak.

To address an exhaust manifold leak and the associated ticking noise:

a. Visual Inspection. Inspect the exhaust manifold and gaskets for any visible signs of damage or leakage. Look for sooty residue, black marks, or rust around the manifold.

b. Tighten Bolts. Sometimes, exhaust manifold bolts can become loose over time due to engine vibrations. If you identify a loose bolt, carefully tighten it to the manufacturer's specified torque.

c. Listen for the Noise. While the engine is running, try to pinpoint the source of the ticking noise. Be cautious, as the exhaust manifold and nearby components can become very hot.

d. Tighten Bolts. Sometimes, exhaust manifold bolts can become loose over time due to engine vibrations. If you identify a loose bolt, carefully tighten it to the manufacturer's specified torque.

e. Replace Gaskets. Exhaust manifold gaskets are designed to create a tight seal between the manifold and the cylinder head. If the gasket is damaged or worn out, it needs to be replaced.

f. Professional Inspection and Repair. If you are unsure about the cause of the ticking noise or if the leak is severe, it's best to have a qualified mechanic inspect and repair the exhaust manifold properly.

g. Preventive Maintenance. Regularly inspect and maintain your vehicle's exhaust system to prevent leaks and potential issues in the future.

Ignoring an exhaust manifold leak can lead to more severe problems, such as damage to the engine components or increased emissions. Addressing the issue promptly will help maintain the performance and efficiency of your vehicle and prevent further complications.

4. Timing Belt or Chain

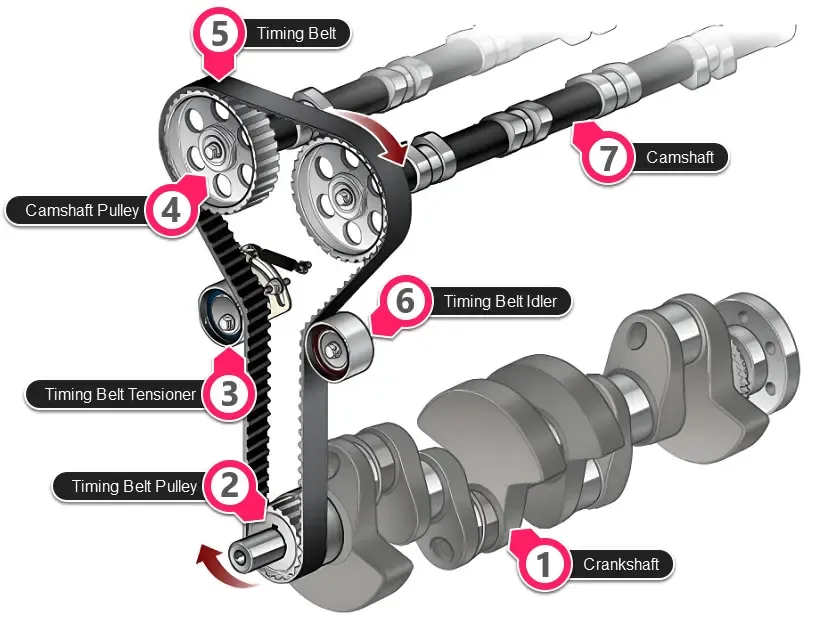

If the timing belt or timing chain is worn or loose, it may cause a ticking noise. The timing components are responsible for synchronizing the rotation of the camshaft and crankshaft, and any issues with these components can lead to noise.Timing Belt

The timing belt or timing chain in a vehicle is responsible for synchronizing the rotation of the engine's camshaft(s) and crankshaft. It ensures that the engine's valves open and close at the right time during each cylinder's intake and exhaust strokes. If there is a ticking noise related to the timing belt or timing chain, it could indicate potential issues that need attention.

Timing Belt Ticking Noise:

a. Tensioner Issues. The timing belt is kept under tension by a tensioner. If the tensioner is worn or faulty, it may not keep the belt tight, causing it to slap against the engine components and create a ticking noise.

3: Timing Belt Tensioner

b. Misalignment. A worn or improperly installed timing belt can become misaligned, resulting in noise as it rubs against the pulleys or other engine components.

c. Timing Belt Wear. Over time, the timing belt can wear, leading to visible cracks or fraying. A damaged belt can produce noise as it interacts with the pulleys.

Belt Tension Adjustment Needed. If the timing belt is too loose, it can cause noise as it moves and slips on the pulleys.

Timing Chain Ticking Noise:

a. Timing Chain Tensioner Issues. The timing chain is also equipped with a tensioner to maintain proper tension. If the tensioner is worn or malfunctioning, it can cause the timing chain to slap against the guides or engine parts, leading to a ticking noise.

Timing Chain

b. Timing Chain Wear. Timing chains are designed to last longer than timing belts, but they can still wear out over time. A stretched or worn timing chain may produce noise as it interacts with the chain guides and sprockets.

c. Lack of Lubrication. Insufficient oil supply to the timing chain can cause it to generate noise due to increased friction.

d. Timing Chain Guide Damage. The chain guides keep the timing chain in place. If they become damaged or worn, the timing chain can make a noise as it moves around.

e. Variable Valve Timing (VVT) System Issues. Some engines have a VVT system that uses oil pressure to adjust camshaft timing. Problems with the VVT system can cause noise related to the timing chain.

If you are experiencing a ticking noise that seems to be coming from the timing belt or timing chain area, it is crucial to have the issue diagnosed and repaired by a qualified mechanic as soon as possible. Ignoring timing belt or chain issues can lead to severe engine damage if they fail or slip, causing the engine's valves and pistons to collide.

Regular maintenance, such as replacing the timing belt or timing chain as per the manufacturer's recommended intervals, can help prevent issues and ensure the proper functioning of the engine's timing system. Always follow the maintenance schedule outlined in your vehicle's owner's manual to keep your engine in good working condition.

5. Spark Knock

Spark knock or detonation occurs when the air-fuel mixture in the cylinders ignites prematurely. This can produce a ticking or pinging sound. It is often caused by improper fuel octane rating, carbon buildup, or issues with the ignition timing.Spark knock, also known as engine knock or pinging, is a knocking or pinging noise that occurs in an internal combustion engine. It is caused by the premature ignition of the air-fuel mixture in the engine's cylinders. Instead of being ignited by the spark plug at the proper timing, the fuel-air mixture ignites too early, leading to the knocking sound.

The knocking noise occurs when the expanding flame front from the early ignition collides with the regular flame front initiated by the spark plug. This collision creates pressure waves that produce the characteristic knocking sound.

Causes of Spark Knock:

a. Low Octane Fuel. Using gasoline with an octane rating lower than what your vehicle's engine requires can lead to spark knock. High-performance or high-compression engines typically require higher-octane fuel to prevent knocking.

b. Carbon Deposits. Carbon deposits can accumulate in the combustion chamber over time, increasing the likelihood of spark knock.

c. Engine Overheating. High engine temperatures can cause the air-fuel mixture to ignite prematurely, leading to knocking.

d. Excessive EGR (Exhaust Gas Recirculation). An issue with the EGR system can result in an excessive amount of exhaust gases being recirculated into the intake, leading to a spark knock.

e. Faulty Ignition Timing. Incorrect ignition timing can cause the air-fuel mixture to ignite too early, resulting in a spark knock.

f. Lean Air-Fuel Mixture. A lean air-fuel mixture (too much air and insufficient fuel) can increase the likelihood of a spark knock.

g. Carbon Knock. This is a specific type of knock caused by carbon deposits in the combustion chamber, which can become red hot and ignite the fuel prematurely.

How to Address Spark Knock:

a. Use the Correct Octane Fuel. Make sure you are using fuel with the octane rating recommended by your vehicle's manufacturer. Using higher-octane fuel than necessary won't provide any benefits and is unnecessary.

b. Clean Carbon Deposits. Regularly using fuel additives or fuel system cleaners can help remove carbon deposits from the combustion chamber.

c. Address Engine Overheating. Ensure that your vehicle's cooling system is working correctly to prevent overheating.

d. Check Ignition Timing. If the ignition timing is off, have it adjusted to the manufacturer's specifications.

e. Inspect EGR System. Have the EGR system checked for proper operation and clean the EGR valve if necessary.

EGR System

Address Lean Air-Fuel Mixture. If the engine is running too lean, have it diagnosed by a mechanic to identify the underlying issue.

Persistent spark knock should not be ignored, as it can lead to engine damage over time. If you are unable to determine the cause of the spark knock or if it persists even after trying the above steps, it's best to have your vehicle inspected by a qualified mechanic to diagnose and resolve the issue properly.

6. Loose Components

Vibrating or loose components within the engine can create ticking noises. It's possible that a bolt or other part has come loose and is causing the noise. Inspecting and tightening the engine components may resolve the issue.Common Areas where Loose Components can Cause Engine Ticking Noises

If you are experiencing a ticking noise coming from the engine bay due to loose components, it's essential to address the issue promptly to prevent any potential damage to the engine and ensure the vehicle's optimal performance. Here are some common areas where loose components can cause engine ticking noises:

a. Valve Train Components. The valve train consists of various components like rocker arms, lifters, pushrods, and camshafts. If any of these parts become loose or worn, they can produce a ticking noise as they vibrate and interact with each other.

b. Timing Chain or Timing Belt Components. If the timing chain or timing belt is loose or improperly tensioned, it can create a ticking noise as it moves along the gears or pulleys.

c. Heat Shields. Loose heat shields around the exhaust manifold or other exhaust components can vibrate and create a ticking sound.

d. Loose Belts. A loose serpentine belt or accessory belt can cause a ticking noise as it moves over the pulleys and accessories.

e. Intake Manifold Components. Loose intake manifold components or gaskets can cause a ticking noise as they leak air and affect the air-fuel mixture.

f. Fasteners and Bolts. Loose bolts or fasteners in the engine bay can vibrate and produce ticking sounds.

To address engine ticking noises caused by loose components:

a. Visual Inspection. Perform a visual inspection of the engine bay to look for any visibly loose components, bolts, or fasteners.

b. Tighten Bolts and Fasteners. Carefully tighten any loose bolts or fasteners you find, but be cautious not to overtighten them.

c. Inspect Valve Train. If the ticking noise seems related to the valve train, it's best to have a qualified mechanic inspect and adjust the valve lash or replace any worn components.

d. Check the Timing Chain or Timing Belt. If you suspect an issue with the timing chain or timing belt, have a mechanic inspect and adjust or replace them as necessary.

e. Exhaust System Inspection. Have the exhaust system inspected for loose heat shields and other components that may be causing the noise.

f. Check Belts. Inspect the serpentine belt and accessory belts for proper tension. Adjust or replace them if needed.

g. Intake Manifold Inspection. Have the intake manifold and related components inspected for any leaks or loose parts.

If you are not confident in identifying or addressing the issue yourself, it's recommended to have a qualified mechanic diagnose and repair the problem. They can pinpoint the source of the ticking noise and perform the necessary repairs or adjustments to ensure your engine operates smoothly and quietly. Ignoring engine ticking noises caused by loose components could lead to more significant problems in the future, so it's best to address them promptly.

It is important to note that diagnosing the specific cause of the ticking noise without a physical inspection can be challenging. If you're not familiar with engine diagnostics and repairs, it's recommended to take your vehicle to a qualified mechanic who can accurately identify and resolve the problem. They will be able to perform a thorough inspection and provide the necessary repairs or maintenance.

How Much Does It Cost To Fix A Ticking Engine?

The cost to fix a ticking engine can vary widely depending on several factors, including the underlying cause of the ticking noise, the make and model of the vehicle, and where you're getting the repair done. Ticking noises in an engine can be caused by a variety of issues, such as valve train problems, worn lifters, low oil levels, or other mechanical problems.

Here are some rough estimates of potential costs for fixing a ticking engine:

1. Valve Adjustment: If the ticking noise is due to improper valve clearance, a valve adjustment might be necessary. This could cost anywhere from $100 to $300 or more, depending on the complexity of the engine and the labor rates of the repair shop.

2. Lifter Replacement: Worn lifters could be causing the ticking sound. Replacing lifters can range from $200 to $500 or more, depending on the type of lifters and the vehicle.

3. Oil Change and Maintenance: Sometimes, a ticking noise can be resolved by simply changing the oil and using the correct oil grade recommended by the manufacturer. This might cost around $50 to $100.

4. Timing Chain or Belt Replacement: If the ticking noise is related to the timing chain or timing belt, the cost can vary significantly based on the complexity of the engine design. This could range from a few hundred dollars to over a thousand dollars.

5. Other Mechanical Repairs: If the ticking noise is indicative of a more serious mechanical problem, such as a damaged engine component, the cost could be much higher. Major engine repairs might cost several thousand dollars.

6. Labor Costs: Labor rates can vary depending on where you live and the reputation of the repair shop. Rates could range from $50 to $150 or more per hour.

It's important to note that these are rough estimates, and actual costs can vary widely. It's recommended to have the vehicle inspected by a qualified mechanic to determine the exact cause of the ticking noise and receive an accurate cost estimate for the repair. Additionally, addressing the issue early can help prevent further damage to the engine, potentially saving you money in the long run.

Engine Ticking Noise When Cold

A ticking noise in the engine that occurs precisely when the engine is cold can be attributed to several factors. Cold temperatures can cause certain components to contract and create more audible noises. However, it's still important to ensure that the ticking noise is not a sign of a deeper issue. Here are some common reasons for a cold-start ticking noise:

Lifter Noise. Hydraulic valve lifters can sometimes create a ticking noise, especially when the engine is cold. As the engine warms up, oil circulates and the lifters become fully pressurized, which often reduces or eliminates the noise.

Exhaust Manifold Expansion. Cold-start ticking could be related to the exhaust manifold or headers. Metal parts in the exhaust system may contract due to the cold, and as the engine warms up, they expand. This expansion could cause ticking noises.

Timing Chain or Belt Tension. Cold temperatures might affect the tension of the timing chain or timing belt. If the tension isn't ideal when starting the engine in the cold, it could lead to a ticking noise until the components warm up and reach the proper tension.

Oil Viscosity. Cold oil tends to be thicker and flows less effectively compared to warm oil. If the oil is not flowing properly through the engine's components, you might hear ticking noises. Using the correct viscosity oil for your engine and allowing it some time to circulate during startup can help alleviate this.

Accessory Belts. Belts that drive accessories like the alternator, power steering pump, or air conditioning compressor can cause ticking noises when cold and haven't yet achieved optimal flexibility.

Heat Shields. As mentioned earlier, metal components like heat shields can expand and contract with temperature changes, leading to ticking noises during cold starts.

Fuel Injectors. Some fuel injectors might make a clicking noise when they are operating. This is normal and more noticeable during cold starts due to the quiet surroundings.

Exhaust Valve Clearance. If your engine uses solid lifters or overhead camshafts with adjustable clearances, the cold might affect the valve clearance and cause ticking noises until the engine warms up.

In most cases, these ticking noises during cold starts are benign and are just a result of the normal behavior of engine components in response to temperature changes. However, suppose the noise is excessive, persistent, or accompanied by other symptoms like poor engine performance. In that case, you should consider having a professional mechanic inspect the vehicle to rule out any underlying issues. Regular maintenance, including using the correct oil, maintaining proper tension on belts, and following manufacturer recommendations, can help minimize these noises.

Help us expand the people we help by sharing this information with others. Thank you !!!

Share with us what you think about this topic to provide another reader more information that this article should have covered.